Abstract

On July 20, 1969, astronaut Neil Armstrong became the first person to walk on the moon. Over the next 3 years, 11 others followed in his footsteps. However, astronauts have not returned to the moon in nearly 50 years. Since then, scientists have talked about sending people back to the moon or even to Mars. Some scientists want to establish permanent colonies in space in case resources ever run out on Earth. But how do you build places to live and work in an area with no construction materials, equipment, or workforce? One promising solution may be three-dimensional printing.

What Is 3D-Printed Construction?

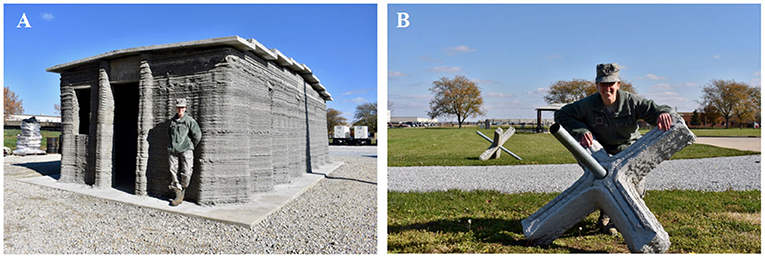

You may have heard of three-dimensional (3D) printing, a new way to manufacture things we use every day. 3D printing can be used to make toys, food, human organs, and more! 3D printers squeeze out material, such as plastic, metal, or wood in layers to make 3D objects. Did you know 3D printing is also being used to build houses, offices, and other buildings? This method of 3D-printed construction was invented in 1998 but has really grown in the past 5 years. 3D-printed construction squeezes out building materials like concrete to form walls, components, such as beams and columns, and even entire buildings. There is no limit to the types and shapes of structures that 3D printing can create (Figure 1).

- Figure 1 - Two examples of 3D-printed construction here on Earth.

- (A) The author with a concrete barracks hut used to house military troops on deployment. The walls of the barracks hut were 3D-printed in <48 h! (B) The author with a hedgehog barrier, which is a type of vehicle obstacle that helps secure and defend military bases. As you can see, 3D-printed construction can be used for all kinds of structures.

Some scientists want to establish permanent colonies and structures in space in case resources ever run out on Earth. Structures that may be useful in space include shelters, shuttle hangars, roads, landing and launch pads, and blast protection walls [1]. As humans spend more time in space, more complex structures may also be required, including research labs, garages, greenhouses, and other long-term buildings.

3D printing in space has two big advantages compared to traditional construction. First, buildings can be printed using materials found in space, like crushed rocks and dust. Second, 3D printing requires few or no workers. This means colonies could be ready for astronauts to move into before they even arrive.

Space Materials: Moon Rock and More

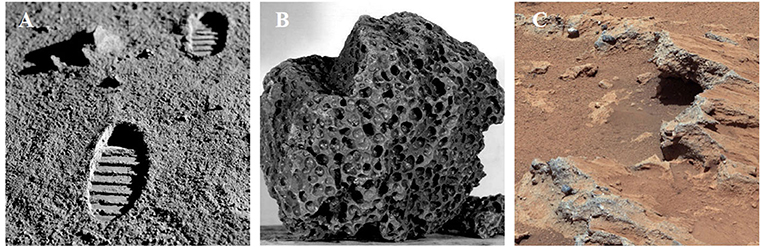

Space shuttles and rockets have limited cargo space and do not fly too often, so sending supplies into space is expensive. In fact, it costs as much as $1 million per kilogram to send supplies to Mars [2]! For this reason, building with space materials can save billions of dollars. Three common space materials are regolith, basalt, and sulfur (Figure 2). Scientists are working on technology to harvest and process these materials for use in construction.

- Figure 2 - Materials found in space.

- (A) Regolith, the crushed rock that covers the moon’s surface. (B) Basalt, an igneous rock found on the moon. (C) The dust on Mars, which contains a material called sulfur.

Regolith is the layer of crushed rock and dust produced on the moon’s surface after centuries of micrometeorite strikes. It is the simplest and most common material used in 3D-printed construction in space. Basalt is an igneous rock, meaning it is formed during lava flow. It makes up roughly 26% of the surface of the near side of the moon. Basalt resists radiation from the sun and can be used to build pressurized structures. Sulfur is a material common to Mars. It is sometimes used in concrete to help the other ingredients stick together better.

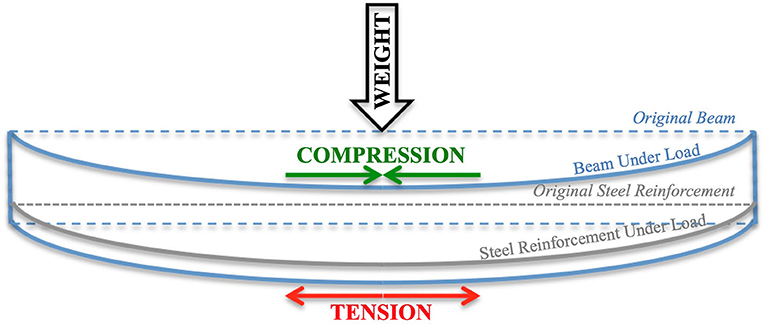

Potential building materials are plentiful in space. However, reinforcing materials, such as steel are not. On Earth, steel provides buildings with extra strength to help them resist stretching forces, which are called tension or tensile forces. Without steel, concrete structures can crack and break. To reduce the need for steel, buildings can be designed to rely on compression [3]. Compression is the opposite of tension. It occurs when concrete is loaded with weight and compacted (pressed by the load). Two examples of compression-based designs are arches and domes.

Figure 3 shows how a reinforced concrete beam can experience both compression and tension. Beams are a basic part of many buildings, and they support weight, like floors, roofs, and people. Because the moon’s gravity is 83% weaker than gravity on Earth, space structures experience less tensile and compressive forces. This allows engineers to print lighter, slimmer structures, and use less materials [3].

- Figure 3 - Weight produces both compression and tension in reinforced concrete beams.

- The original beam (blue dotted lines) is straight. When weight is applied to a beam, it bends under the load (blue solid lines). The top of the beam shortens (compresses) as it bends. This is a good thing because concrete is strong under compression. The bottom of the beam lengthens and stretches as it bends (tension). This is a challenge because concrete is weak under tension. However, placing a reinforcing steel rod at the bottom of the beam (gray line) helps control the tension.

Construction by Printers, for Humans

3D printing can be used to build colonies on the moon and Mars even before humans arrive. Building in advance helps keep astronauts safe when they arrive in space. For example, buildings protect astronauts from solar radiation and space debris. Pressurized buildings can even give astronauts a place to live and work without needing their spacesuits.

Unlike human workers, printers do not need air, water, or food. This saves money and makes space construction easier. Also, unlike humans, printers do not need to stop to rest. This means 3D printing can be completed faster than normal construction. Compared to humans, printers are also more reliable and consistent. When programmed properly, printers reduce mistakes, increase safety, and improve the quality of construction. Better construction with fewer errors means less time and money spent fixing things that were not done correctly the first time.

How to Print

In 2015, NASA invited teams from all over the world to a 3D-printing competition. It was called the 3D-Printed Habitat Challenge, and it gave out $2.5 million in prizes. The competition took place in three phases. First, each team submitted their best habitat design. Next, the teams developed materials to print with based on what is available in space. Finally, the teams 3D-printed their designs using their materials. The goal of the competition was to improve the way NASA will build structures in space. In the end, some ideas were more successful than others. However, each idea helped NASA understand what may or may not work in space. For example, dome and bubble designs both seem promising. Teams were successful using both space materials and recycled trash in their printing mixes. However, one big challenge NASA must address in the future is scalability, or the ability to make the structures full size. Engineers know that designs that work well in models are not always as good when built full-size. NASA and companies like Made in Space are working on improving the scalability of 3D-printed construction.

One possible approach to in-space 3D printing is a method called contour crafting. Contour crafting first squeezes out material in layers. Then, it uses built-in spreading tools called trowels to shape the layers into smooth surfaces. The troweling process allows for higher quality finished structures. Contour crafting captured NASA’s interest for three main reasons. First, it is one of the most reliable and established 3D printing methods here on Earth. Second, it can be used to print needed structures safely and cheaply. Third, contour crafting works with space materials like regolith.

One research team wants to combine contour crafting with a robotic system called ATHLETE [4]. ATHLETE stands for All-Terrain Hex-Limbed Extra-Terrestrial Explorer. ATHLETE is “All-Terrain” because it can travel across uneven lunar or planetary surfaces. “Hex-Limbed” means ATHLETE has six arms. These arms allow it to use several tools to navigate and build components. Finally, the term “Extra-Terrestrial” means ATHLETE is designed to be used in space. It collects energy from the sun and uses it as a source of renewable power. This means it does not have to be plugged in or supplied with fuel to run.

Looking Forward

3D printing in space faces some unique challenges. It is difficult to print in environments with low gravity [1]. Printers need built-in redundancy (extra parts) in case stuff breaks. If issues do arise, printers must be easy to repair. Printers must be durable enough to work in extreme temperatures, dust storms, and moonquakes [1]. Finally, if printers are unmanned, they need to be able to be controlled from Earth. This means they must be able to operate and communicate over long distances and without delays [3].

Right now, 3D-printed construction is in a stage called proof-of- concept and validation [1]. This means scientists are still learning what 3D printing can do and if it will work in space. To guide the development of 3D printing, they set several goals for the future. By 2040, scientists want to start using 3D-printed construction to build space colonies. By 2065, scientists hope space 3D printing will be able to support colonies long-term. Finally, scientists believe that by 2115, 3D-printed construction in space will be entirely independent of humans and of Earth’s resources [5]!

In the meantime, developing a reliable 3D printing method for space helps advance 3D printing on Earth. For example, building shelters in space teaches us better ways to construct low-cost, quality homes here on Earth. And by finding ways to collect space materials, we can improve the way we obtain resources on Earth. This supports faster, cheaper, and better construction on Earth and in space. Simply put, 3D-printed construction is out of this world!

Glossary

Regolith: ↑ The crushed rock and dust produced on the moon’s surface after centuries of micrometeorite strikes.

Basalt: ↑ An igneous rock commonly found on the near side of the moon that resists radiation from the sun.

Sulfur: ↑ A material commonly found on Mars that is used to help the ingredients of a concrete mix stick together.

Tension: ↑ The state of a beam when it is stretched.

Compression: ↑ The state of a beam when it is pressed and compacted under a load.

3D-Printing: ↑ A process of manufacturing or constructing items and structures by printing them in sequential layers.

Contour Crafting: ↑ A method of 3D printing in which the material is squeezed out in layers and then smoothed out by robotic trowels.

Disclaimer

The views expressed in this paper are those of the authors and do not reflect the official policy or position of the United States Air Force, Department of Defense, or the United States government.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

[1] ↑ Mueller, R. P., Sibille, L., Hintze, P. E., Lippitt, T. C., Mantovani, J. G., Nugent, M. W., et al. 2014. Additive Construction Using Basalt Regolith Fines. Available online at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84936748071&doi=10.1061%2f9780784479179.042&partnerID=40&md5=e6a74f7a3e2d91b587222c4a1d49d302

[2] ↑ Howe, A. S., Wilcox, B., McQuin, C., Mittman, D., Townsend, J., Polit-Casillas, R., et al. Modular Additive Construction Using Native Materials. Available online at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84936803844&doi=10.1061%2f9780784479179.034&partnerID=40&md5=09bf4e34736d6cc394505bd3f466ee62

[3] ↑ Leach, N., Carlson, A., Khoshnevis, B., and Thangavelu, M. 2012. Robotic construction by contour crafting: the case of lunar construction. Int. J. Archit. Comput. 10:423–38. doi: 10.1260/1478-0771.10.3.423

[4] ↑ Howe, S. A., Wilcox, B. H., McQuin, C., Townsend, J., Rieber, R. R., Barmatz, M., et al. 2013. “Faxing structures to the moon: freeform additive construction system (FACS),” in AIAA SPACE 2013 Conference and Exposition (San Diego, CA: American Institute of Aeronautics and Astronautics). doi: 10.2514/6.2013-5437

[5] ↑ Mueller, R. P., Howe, S., Kochmann, D., Ali, H., Andersen, C., Burgoyne, H., et al. 2016. Automated Additive Construction (AAC) for Earth and Space Using In Situ Resources. Available online at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84995371337&doi=10.1061%2f9780784479971.036&partnerID=40&md5=c0311e7e39f28dca5d30dae283825e00