Abstract

United Nations’ Sustainable Development Goal 9 (Industry, Innovation, and Infrastructure) aims to ensure we make things in a sustainable way. Many kinds of equipment and chemicals are needed to make all the products we use every day. This is not an easy task—millions of people all over the world work in giant “kitchens” called chemical industries, where they prepare and mix materials to make everything from the plastic in your toys, the fabric in your clothes, and the medicines that heal sick people. To be sustainable, all industries need to reduce the amounts of energy and materials they use, and the garbage they produce. This challenge requires new ways of making products, and new machines to make those products! The good news is that we have some new high-tech alternatives. In this article, we will tell you how 3D printing can help industries be more efficient, safer, and better for the environment. Watch an interview with the authors of this article to learn even more! (Video 1).

Factories and the Environment

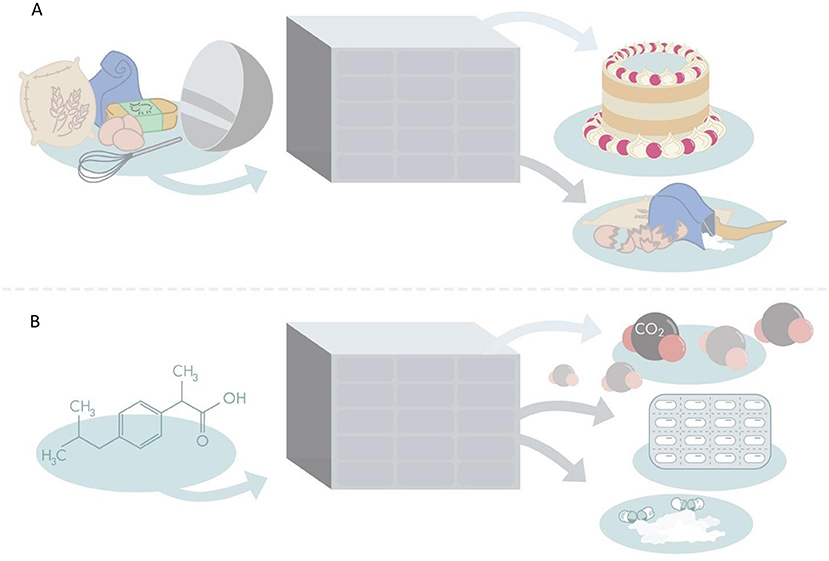

Most of the products we use in our daily lives, like clothes, toys, medicines, and even food, are produced in factories. Scientists use the word industries to talk about factories, and we tell industries apart by what they produce. For example, chemical industries produce many materials to make almost everything around us. The pharmaceutical industry is an example of a chemical industry that produces medicines. Some chemical industries work pretty much like your kitchen. In a kitchen, you can use different ingredients, different recipes, and different equipment to prepare certain foods, like a cake (Figure 1A). When a food needs a long cooking time or a high cooking temperature, it requires more electricity, gas, or wood. In those cases, more carbon dioxide is released to Earth’s atmosphere, which causes the global warming you have probably heard so much about.

- Figure 1 - How factories make things.

- (A) The process of making a cake is similar to (B) the industrial process used to make medicines. Both processes begin with starting materials (ingredients and chemical compounds). The gray boxes represent all the transformations ingredients and chemicals pass through before they become final products, such as a cake or pills. Both processes use energy and produce waste. In the case of the cake, the waste is eggshells and an empty flour bag; for the pills, waste is the emission of carbon dioxide (CO2) and broken or damaged pills that cannot be used.

In some chemical industries, the methods used also consume a lot of energy and materials (Figure 1B). As no process is perfect, some elements are not converted into valuable products and rubbish is often generated. Products produced this way are not very sustainable, meaning that they contribute to damaging our planet. When industries produce medicines and vaccines, they are often focused on saving lives and may pay less attention to the quantity of rubbish generated or to carbon dioxide emissions. However, as Earth’s climate approaches a critical point, we need to reduce the use of materials and emissions when we make all products, including essential ones.

Sustainable Development Goal 9 (Industry, Innovation, and Infrastructure, SDG 9 for short) is one of the 17 Sustainable Development Goals set by the United Nations to keep our planet healthy [1]. SDG 9 aims to make sure that industries adopt sustainable practices and that countries invest in improved infrastructure like roads, bridges, and access to essential services such as clean water and fast internet, to strengthen communities. To make all of this happen, many new scientific and technical developments are required. Also, as climate change is a global problem, it is important that all countries benefit from new, more efficient technologies. By focusing on improving infrastructure and supporting creativity, we can create more jobs, support businesses, and ensure a better quality of life for everyone. Advances in this area are also relevant to other SDGs. For example, having affordable medicines can support SDG 3, which aims to ensure healthy lives for all human beings. Also, improved methods for producing medicines supports SDG 12, which aims to ensure sustainable consumption and production.

To support SDG 9, the things that industries must do are not very different from our own contributions at home: reduce, reuse, and recycle. Industries should reduce the amount of energy and materials used to make their products. After we use products, we should be able to recycle them. Creating new methods to reduce, reuse, and recycle are efforts that will cost money, but if we do not do so, it will be even more expensive to deal with the consequences of climate change and a damaged environment.

The Science of Making Things

Due to science, technology has evolved very quickly in the last few years. Common things in our lives, like cellphones and the internet, were not available when your grandparents and parents were kids. The machines used in industry are expensive and they should last many years. If a not-so-efficient machine is designed to work for many years, it will be a long time until more efficient equipment replaces it. For example, some of the machines used to produce fertilizers normally work for 40–50 years. Industries upgrade their machines and manufacturing processes at different speeds, but they all need to switch to more sustainable ones in the years to come.

As an example, let us look at an industry where millions of people work: the pharmaceutical industry. Thanks to its products, our society has become much healthier, and people can now live longer. The pharmaceutical industry manufactures the medicines we take when we get sick. As you saw in Figure 1, medicines are produced in a way similar to cooking food. Like using pans for cooking, factories use vessels called reactors. Instead of food, they transform various chemicals into medicines. This transformation takes time and usually produces a mixture of compounds, including some we do not want or need. Production and purification processes consume a lot of materials and money. Medicine production also generates a lot of rubbish: on average, for every kg of medicines sold, there are more than 25 kg of materials going to waste [2]. Medicines for specific diseases can have many stages of production and generally produce even more waste. That is also why they are more expensive. Could there be a better way to produce the medicines everyone needs?

Improving the Way We Make Things

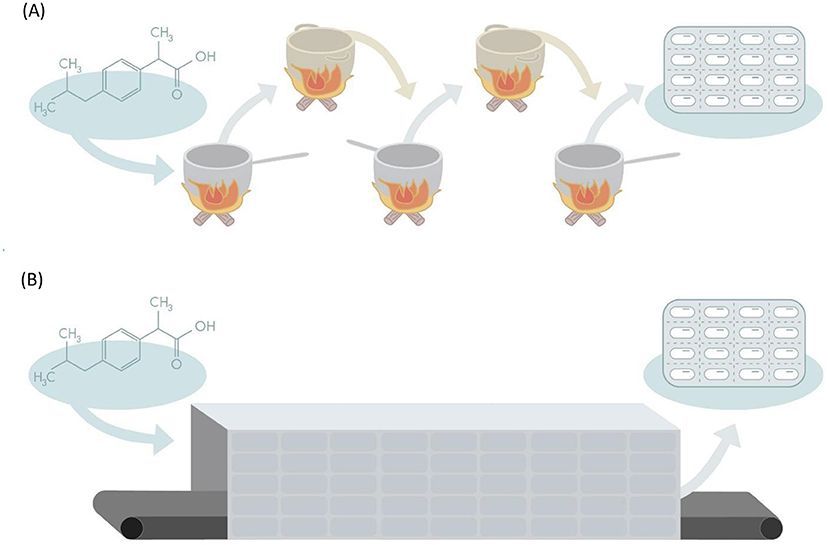

If we want to make medicines available to more people around the globe, we need cheaper and more sustainable manufacturing. However, we cannot trade cost for quality: we need to be sure that medicines cost less but keep the same quality, safety, and effect. Because the quality standards of the pharmaceutical industry are so high, production usually happens in stages, transforming chemicals in different reactors (Figure 2A). This prevents the factory from losing all their chemicals if the process does not work well. It also makes it easier to remove bad batches of medicine from the market if someone has a bad reaction. That is why all medicine boxes have a batch number. But a new process called continuous manufacturing avoids the use of batches by using other ways to control the reactions and the quality of medicine production (Figure 2B) [4]. It also makes medicines faster! But how can we make continuous manufacturing reactors?

- Figure 2 - Different methods used to produce medicines.

- (A) When we use regular reactors in batch manufacturing, some medicines take a long time to be produced, and the final product needs a lot of purification. Also, large equipment can make it hard to achieve good mixing and a constant temperature. (B) Because of these challenges, scientists developed continuous manufacturing. In this process, the mixing of chemicals in the reactors happens quicker, and the entire process is more controlled, making it faster and more compact. Fewer purification steps are also needed.

3D Printing—A New Way to Make New Things

Similar to achieving the right flavors while cooking, some chemical reactions are not easy to perform and control. For example, when you are cooking something and the temperature is very high, the food may burn or not taste good. This is because unwanted chemical reactions happen. When medicines are produced, if the temperature is not well controlled, a toxic compound can be produced along with the medicine. This is just one example, but there are several different problems, and each of them needs to be addressed during production. While there are many possible solutions, most rely on using more resources or making the production process longer. These approaches can make the products more expensive.

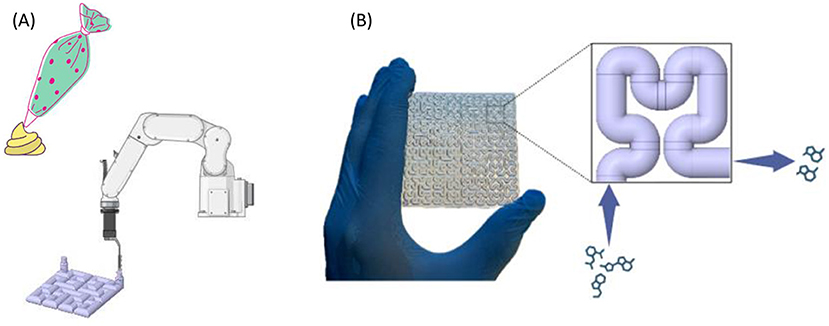

Figure 3 shows one of the reactors we produced, called a fractal reactor [3]. A fractal is a mathematical definition of a shape where a pattern repeats itself many times, like the branches of a tree. Fractal reactors could help make certain medicines in a faster, more sustainable way. The best news is that we can update the shape of the reactor very easily. Our main target is to improve the shape of the reactor to make a product while reducing the amounts of resources and energy needed.

- Figure 3 - (A) 3D printing is like decorating a cake using a piping bag.

- When you squeeze a piping bag filled with frosting and move the tip of the bag, you can create different designs. In 3D printing, the printer is filled with a material that is liquid when it leaves the nozzle, but that solidifies when it touches a colder surface. (B) A fractal reactor 3D printed using transparent plastic. The enlarged area shows the reactor’s tiny hollow tubes where chemicals get mixed. Through the many twists, molecules are transformed, resulting in the targeted chemical. (Image created with BioRender).

One possibility for producing fractal reactors for continuous manufacturing containing difficult reactions is by using 3D printing. One advantage of 3D printing is that it can produce very complicated shapes that could not be created before. Our research group designs and manufactures new reactors to try to control complicated reactions. For example, we can work with dangerous acids in safer ways and in more compact units than before [4]. We are basically doing the same thing you do when you select clothes—we choose the right size and the right features of the clothes for each of the tasks that we need! There is no need to wear a suit and tie to go surfing!

The Industries of the Future

Industries are one of the pillars of our wellbeing and are fundamental to human societies. SDG 9 aims to ensure that countries are doing their best to make all industries more sustainable. New technologies like 3D printing can help industries create products that use fewer resources, while generating less rubbish and carbon emissions. In the pharmaceutical industry, 3D printing can help us to create reactors to make important medicines faster, while keeping their quality. You too can contribute to this, by choosing to buy things made using sustainable production methods. You can also use your imagination to come up with new ways of making things that are better for the planet and people!

Glossary

Industries: ↑ “Factories” where products or services are produced.

Pharmaceutical: ↑ Any drug used with medicinal purposes.

Sustainable: ↑ Products done using less material, using stuff over and over again, and turning old things in new ones, helping the planet by using less stuff.

Infrastructure: ↑ basic systems and services for an organization to work well.

Reactors: ↑ Special machine that by mixing things together, create new things. Many times, by making them really hot.

Purification: ↑ The process used to select only the desired items from a mixture.

Continuous Manufacturing: ↑ Never stopping production of same things over, and over again.

Fractal Reactor: ↑ A device with many turns, which make things bump in each other a lot and making something new.

Molecule: ↑ smallest unit of any substance (H2O represents one molecule of water).

3D Printing: ↑ Making real objects layer by layer from a computer drawing. It is like stacking blocks together to make a building.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

We would like to thank Ruben Costa and Nicki Talbot at KAUST for their invaluable support during the initial writing stage and review process, without which this collection would not have been possible. We would also like to extend our gratitude to the Office of Sustainability and UNDP-Saudi Arabia Country Office for their dedication to raising awareness of the importance of the UN SDGs in our journey toward a more sustainable world. The research presented in this work was supported by the King Abdullah University of Science and Technology (KAUST). Authors acknowledge Ana Bigio as the illustrator of Figures 1, 2.

References

[1] ↑ United Nation 2015. Transforming Our World: The 2030 Agenda for Sustainable Development. Available at: https://sdgs.un.org/2030agenda

[2] ↑ Sheldon, R. A. 2017. The E factor 25 years on: the rise of green chemistry and sustainability. Green Chem. 19:1843. doi: 10.1039/C6GC02157C

[3] ↑ Grande, C. A. 2021. Compact reactor architectures designed with fractals. React. Chem. Eng. 6:144853. doi: 10.1039/D1RE00107H

[4] ↑ Grande, C. A., and Didriksen, T. 2021. Production of customized reactors by 3D printing for corrosive and exothermic reactions. Indus. Eng. Chem. Res. 60:167207. doi: 10.1021/acs.iecr.1c02791