Abstract

Many people live in very big cities, and these mega-cities continue to grow in number and in size. However, living in a mega-city can mean that healthy fruits and vegetables are difficult to get. Vertical farming systems (VFS), farms that grow crops in stacked layers inside buildings, might be a solution. These systems allow farmers to control all environmental conditions, so that plants can grow well. The environments in many VFS stay the same all the time, but to do so, VFS use a lot of energy—mostly for lighting. What if we could change the conditions in VFS throughout the day and the growing cycle to save energy, without harming plant growth? In this article, we will explain how this strategy, which is called dynamic environmental control, can be used to vary the amount and timing of light plants receive, as well as other growth conditions. Farmers could use many sensors to monitor the plants, to make sure they still grow well and stay healthy under the changing conditions—saving money while producing lots of healthy food!

People Need Healthy Food: A Look into the Future

Have you ever walked into a local market or grocery store and admired the colorful piles of fresh fruits and vegetables? For many of us, it is easy to buy fresh, tasty produce close to home. A healthy diet, containing plenty of veggies and fruits, helps to keep our bodies strong and our minds sharp. However, in many places, eating healthy is not so easy. For example, in massive mega-cities, where lots and lots of people live, access to healthy fruits and vegetables can be limited. Similarly, in extreme environments like deserts, or in exceptionally cold and dark northern regions, growing food—and therefore eating healthy—can be tough.

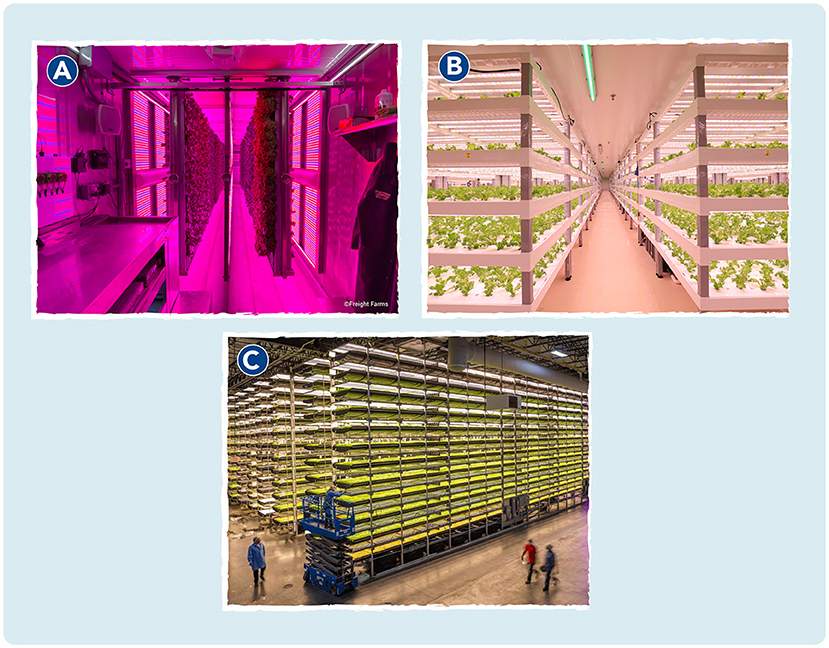

Now, picture a skyscraper in the middle of a city. Instead of offices or apartments, inside this building are rows of fresh vegetables and herbs, growing in closely monitored conditions under bright lights. These plants are not just spread out on a flat surface—they grow in stacked layers, one above the other, reaching up many stories high. This is a vertical farm (Figure 1). Vertical farming helps farmers to make the best use of the limited space in cities, and it offers a way to grow healthy, perishable food close to where people live, reducing the need to transport it over long distances, which can be bad for the environment and for the quality of the produce [1].

- Figure 1 - Vertical farming can help farmers make good use of limited space.

- (A) In this VFS, inside a shipping container, plants are grown in vertical walls. (B) This VFS is located inside a building, and the plants are grown on stacked shelves. (C) Plants are also grown on stacked shelves in this VFS, which is inside a warehouse [photos supplied by (A) Freight Farms, (B) Sananbio, and (C) AeroFarms; figure adapted from [2], Nature Food; used with permission].

What is So Great About Vertical Farming?

There are several big differences between vertical farming and the traditional type of farming that happens outdoors, in fields (Figure 2). In some ways, vertical farming is better for the environment because it uses less land, water, and fertilizer than traditional farming [2–4]. Plus, since the plants are grown indoors, there are fewer pests and diseases, so farmers might not need to use as many pesticides or other potentially harmful chemicals to keep the plants healthy. However, building the vertical farm and equipping it with a large number of electronics—especially LED lamps for lighting and a very big air conditioning system—requires large amounts of energy, materials, and money, even before the first plant is grown. For example, building a new vertical farm costs between 8 and 15 times as much as building a modern greenhouse of the same size.

![Figure 2 - Main differences between open-field farming and vertical farming [figure adapted from [2], Nature Food, with permission].](https://www.frontiersin.org/files/Articles/1454051/frym-12-1454051-HTML-r1/image_m/figure-2.jpg)

- Figure 2 - Main differences between open-field farming and vertical farming [figure adapted from [2], Nature Food, with permission].

One of the best things about VFS is that, since the plants are grown indoors, farmers can create a controlled environment in which every aspect of the plant’s surroundings—like light, temperature, nutrients, and humidity—can be watched closely and adjusted to ensure the plants grow well. With VFS, farmers never have to worry about too much (or too little) rain, or an unexpected cold spell that ruins the harvest. Even better, in VFS crops can be produced all year round, no matter what the weather is like outside—even in the dead of winter! With year-round production, vertical farming can help ensure a steady and consistent supply of fresh produce.

The Biggest Challenge: Energy Use

Keeping all the environmental conditions constant is a huge advantage, but it can also use a lot of energy—particularly for lighting and air conditioning. Electricity use makes up 20–40% of the cost of running VFS; consequently, growing 1 kg of leafy greens costs 3–4 times more in vertical farms than in a modern greenhouse. You probably know that plants growing in fields use sunlight to perform photosynthesis—the process by which they turn carbon dioxide and water into sugars, to fuel their growth. But there is not much sunlight inside tall buildings in the middle of the city, right? This means that special lights in VFS need to be on for long periods to simulate sunlight—and powering these lights requires lots of electricity: 60–85% of the electricity used by VFS is used for lighting. Also, as they grow, plants release large amounts of water vapor, which must be filtered out of the air using specialized air conditioning units. High energy usage not only makes VFS expensive to run, but is also not great for the environment, since fossil fuels like coal are often burned to produce the electricity needed. Hopefully, in the near future, more of that electricity could come from “green” energy sources such as solar panels—but installing these also requires lots of materials and land.

To make VFS more sustainable and less expensive, scientists are exploring ways to use energy more efficiently. One smart idea is to use a process called dynamic environmental control, in which the conditions in the VFS are adjusted throughout the day and according to the growth cycles of the plants. This way, the plants still get what they need to grow, but energy use is optimized, saving money and the environment.

Dynamic Environmental Control: Smarter Indoor Farming

Even if you have looked at your family’s electricity bill, you might not be aware that electricity prices vary throughout the day. Power companies often charge more for electricity during the times of the day when more people are using it. On the other hand, sometimes electricity is cheaper at night or during times when there is less demand. If the lights in a vertical farm are kept on at full intensity all the time, even when electricity costs the most, the expense can add up quickly. However, using dynamic environmental control, VFS can take advantage of periods of lower electricity prices, making the whole system more economical.

Besides light, other factors such as CO2 levels, temperature, and airflow can also be adjusted dynamically. Imagine if you could dim the lights in your room for a few minutes every hour, while still being able to see your book clearly enough to read. You would not notice much of a difference, but you would save electricity. Similarly, in VFS, dynamic environmental control involves adjusting the light intensity and other growing conditions, based on what the plants need at various times, and based on the cost of electricity. For example, the lights might be brighter when electricity is cheaper and dimmer when it is more expensive, as long as the total amount of light needed by the plants throughout the day stays the same. This strategy saves energy while ensuring that the plants receive the right amount of light.

For instance, adjusting temperatures dynamically can help with energy savings. Temperature plays a crucial role in plant growth. Plants may grow better at cooler temperatures during certain stages of development and warmer temperatures at others—so there might not be a need to use electricity to keep a VFS at the right temperature all the time. Also, during the night when outdoor temperatures are lower, VFS can take advantage of the cool temps to reduce the need for air conditioning, thus saving energy. During the day, when outdoor temperatures are warmer, the internal temperatures of a VFS can be increased, to maintain a balanced environment for the plants. This approach uses natural changes in the outdoor temperature to create optimal growing conditions while saving energy costs.

Using dynamic environmental control to adjust these parameters, farmers can ensure that the plants have the best growing conditions while using resources like energy and water as efficiently as possible.

Using Sensors to Keep Plants Healthy

But how do farmers know when to adjust lights and other conditions? This is where sensors come in [5]. Sensors are small devices that can act like the eyes, ears, or noses of the farm. They monitor various aspects of the environment and the plants themselves, such as light levels, temperature, humidity, and even how well the plants are growing. These sensors collect data continuously and send it to a powerful computer system that analyzes the information and makes decisions about when to change the environment, to make sure everything is just right for the plants. You can think of it like the sensors on a smartwatch that track your heart rate and activity levels and give you tips on how to stay healthy. In VFS, sensors help ensure that the plants get just the right amount of light, water, and nutrients they need to grow well, even under changing conditions.

Enhancing Plant Growth and Quality

Dynamic control is not just about saving energy—it also has the potential to improve the quality of crops. If you have ever eaten a fresh tomato straight out of the garden, there is a good chance it tasted much better than the average grocery store tomato. That is because homegrown tomatoes often benefit from more natural growing conditions, which can result in richer flavors and better nutrition. Plants grown on large commercial farms are often chosen by farmers for traits like shelf life and the ability to fend off diseases. While these traits are important for making sure that produce can be shipped long distances and that it looks appealing on store shelves, they sometimes come at the expense of taste and nutritional content. This tradeoff means that although grocery store tomatoes might look perfect and last longer, they might not be as flavorful or nutritious.

VFS can help address these tradeoffs. In creating optimal conditions for plant growth, VFS can help plants to make more healthy nutrients, such as vitamins and antioxidants—making vegetables and fruits more nutritious. These beneficial substances often create the vibrant flavors that make garden-fresh produce so appealing. Because VFS are often located closer to urban areas, crops do not need to be bred for a long shelf life or long-distance transport to stores, so farmers and plant breeders can focus on plants with the best flavor and nutritional quality instead.

Making Vertical Farming Better

Even though dynamic environmental control in VFS is very promising, there are many challenges to solve. Plants need different conditions at different times in their growth cycles or different times of the day, which makes it tricky to keep everything balanced. Factors like temperature, humidity, and light all affect each other, so farmers need to keep an eye on these things and adjust them as needed. To do this, they currently rely on their experience, but in the future they may use advanced computer programs that can predict what plants will need and help set the best conditions. As technology gets better, these programs will become easier to use and more accurate, giving farmers better tools to make VFS work well.

Another challenge is finding the best plants to grow in VFS. Most plants are bred to grow well in open fields or in greenhouses, but these plants might not do as well in VFS. Scientists are working on breeding plants that grow well in VFS. They look for plants that do not need a lot of light, grow quickly, and are small enough to fit in the indoor spaces.

The Future of Food—Growing Smarter and Greener

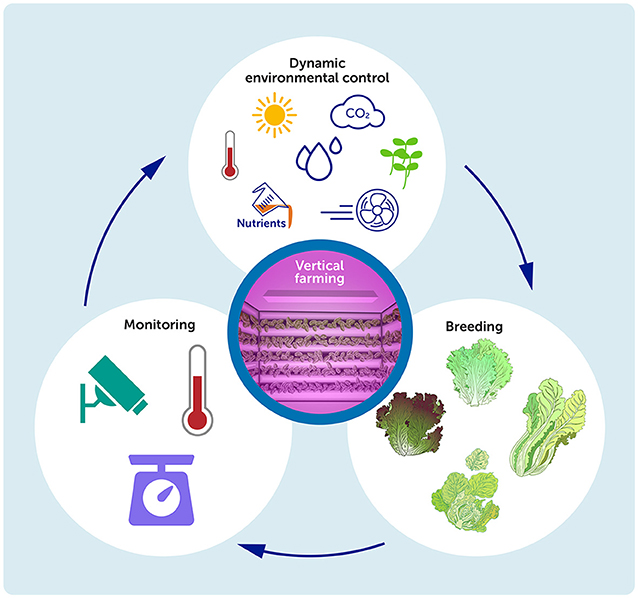

Together, the three critical ideas we have discussed—dynamic environmental control, sensors to check conditions and plant health, and breeding to select the best plants to grow—make VFS an exciting way of farming (Figure 3). By changing things like light, temperature, and CO2 levels throughout the day, VFS can save energy while growing high-quality crops. Looking ahead, breeding plants that grow well in VFS, developing even better sensor technologies, and adding “smart” systems to automatically control the VFS environment will help create the next generation of vertical farms. These new ideas will help us grow more fresh food in big cities, as well as deserts and cold areas, giving us fresh, healthy food all year round. The future of farming is not just about growing up; it is about growing smarter and greener!

- Figure 3 - To optimize food production, VFS can combine three main ideas.

- First, VFS use dynamic environmental control to adjust the growing conditions for plants, which can keep plants healthy and help to save energy. Second, plant breeding techniques can generate plant varieties that grow best in VFS, and possibly even plants that are more nutritious and taste better than their field-grown relatives. Finally, the environment inside the VFS—and even the plants themselves—can be monitored with various types of sensors to make sure conditions are just right for keeping the plants happy (figure adapted from Kaiser et al. [6], Frontiers in Science, with permission).

Glossary

Vertical Farming: ↑ Growing crops in stacked layers or vertical walls inside buildings, using controlled environments for optimal growth. Vertical farming is especially useful in big cities or areas with harsh climates.

LED Lamps: ↑ Lamps that provide the necessary light for plants to grow in vertical farms, simulating sunlight and enabling year-round indoor farming, while using less energy compared to traditional lighting.

Photosynthesis: ↑ The process by which plants use light to change carbon dioxide and water into sugars, fueling their growth and producing oxygen as a byproduct.

Sustainable: ↑ Using resources wisely so we can meet our needs today without harming the environment or running out of resources for future generations.

Dynamic Environmental Control: ↑ Adjusting conditions like light, temperature, and humidity throughout the day to save energy and help plants grow better in indoor farms.

Growth Cycle: ↑ The stages a plant goes through from seed to mature plant, including germination, growth, flowering, and fruiting.

Sensors: ↑ Devices that monitor conditions like light, temperature, and humidity, helping farmers ensure plants get what they need to grow well.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

LM received support from the TTW Perspectief programme “Sky High”, which was funded by the Dutch Research Council (NWO), AMS Institute, Bayer, Bosman van Zaal, Certhon, Fresh Forward, Grodan, Growy, Own Greens/Vitroplus, Priva, Signify, Solynta, Unilever, and Van Bergen Kolpa Architects, as well as the Foundation for Food and Agriculture Research. Edited by Susan Debad Ph.D., graduate of the University of Massachusetts Graduate School of Biomedical Sciences (USA) and scientific writer/editor at SJD Consulting, LLC. We would like to thank the coauthors of the original manuscript: Paul Kusuma, Silvere Vialet-Chabrand, Kevin Folta, Ying Liu, Hendrik Poorter, Nik Woning, Samikshya Shrestha, Aitor Ciarreta, Jordan van Brenk, Margarethe Karpe, Yongran Ji, Stephan David, Cristina Zepeda, Xin-Guang Zhu, Katharina Huntenburg, Julian C. Verdonk, Ernst Woltering, Paul P. G. Gauthier, Sarah Courbier, and Gail Taylor.

Original Source Article

↑Kaiser, E., Kusuma, P., Vialet-Chabrand, S., Folta, K., Liu, Y., Poorter, H., et al. 2024. Vertical farming goes dynamic: optimizing resource use efficiency, product quality, and energy costs. Front. Sci. 2:1411259. doi: 10.3389/fsci.2024.1411259

References

[1] ↑ Kozai, T., Niu, G., and Takagaki, M. eds. 2016. Plant Factory—An Indoor Vertical Farming System for Efficient Quality Food Production. Amsterdam: Elsevier Inc.

[2] ↑ van Delden, S. H., SharathKumar, M., Butturini, M., Graamans, L. J. A., Heuvelink, E., Kacira, M., et al. 2021. Current status and future challenges in implementing and upscaling vertical farming systems. Nat. Food 2:944–56. doi: 10.1038/s43016-021-00402-w

[3] ↑ Ji, Y., Kusuma, P., and Marcelis, L. F. M. 2023. Vertical farming. Curr. Biol. 33:471–3. doi: 10.1016/j.cub.2023.02.010

[4] ↑ SharathKumar, M., Heuvelink, E., and Marcelis, L. F. M. 2020. Vertical farming: moving from genetic to environmental modification. Trends Plant Sci. 25:724–7. doi: 10.1016/j.tplants.2020.05.012

[5] ↑ Steeneken, P. G., Kaiser, E., Verbiest, G. J., and ten Veldhuis, M.-C. 2023. Sensors in agriculture: towards an internet of plants. Nat. Rev. Methods Prim. 3:60. doi: 10.1038/s43586-023-00250-x

[6] ↑ Kaiser, E., Kusuma, P., Vialet-Chabrand, S., Folta, K., Liu, Y., Poorter, H., et al. 2024. Vertical farming goes dynamic: optimizing resource use efficiency, product quality, and energy costs. Front. Sci. 2:1411259. doi: 10.3389/fsci.2024.1411259