Abstract

Have you ever wondered what happens to the leaves on berry plants after we pick and eat the berries? People usually think that berry leaves have little value, but studies have shown that berry leaves contain many things that are good for our health. If these substances can be extracted from the leaves, these natural extracts could be used by many industries to improve their products, for example health supplements and skincare products. In our work, we wanted to extract natural substances from berry leaves using a method that is simple and non-toxic, using just alcohol, salt, and water and it is known as the salting-out method.

Why Focus On Berry Leaves?

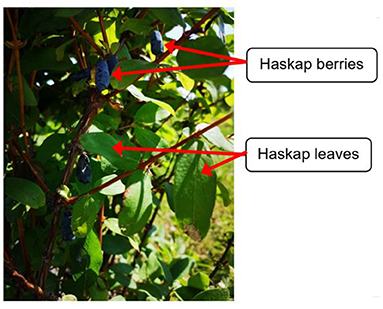

Imagine a strawberry farm with rows of bright red berries waiting to be harvested. But what about the berry leaves? The leaves of berry plants are generally viewed as waste products of berry farms. In the past, berry leaves were sometimes used to make medicinal teas. Research has shown that these leaves are often rich in substances known as bioactive compounds, which can promote good health [1]. For example, blueberries contain vitamin C and compounds called anthocyanins, both of which are antioxidants—substances that may prevent damage to our body cells [2]. In North America, the haskap plant, also known as blue honeysuckle, is gaining popularity. Haskap berries look like a cross between grapes and blueberries, and they have high levels of bioactive compounds (Figure 1) [3]. Although haskap plants are grown commercially for their berries, nothing is done with the leaves after they shed in autumn. In our study, we wanted to see if we could produce a natural bioactive extract from haskap leaves, turning them from an agricultural waste into a useful product.

- Figure 1 - Haskap plants have dark blue berries and lots of green leaves.

- The haskap berries are harvested when ripe, and the leaves eventually fall from the plants in autumn. Since the leaves contain bioactive compounds, we wondered if we could produce a natural extract from them.

Why Extract Bioactive Compounds?

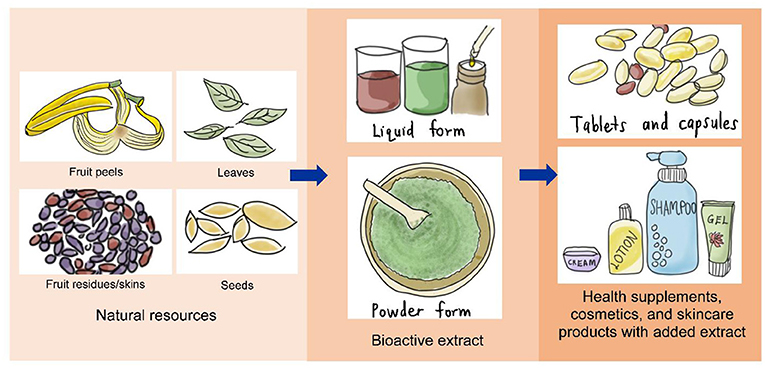

Bioactive compounds usually occur in small amounts in the leaves, stems, seeds, and peels of various fruits and vegetables. Extraction is the process by which specific compounds are separated from their source which, in our case, is haskap leaves. Bioactive extracts are important because the bioactive substances are more concentrated in the extracts than in the leaves themselves. Bioactive extracts can be added to many different products to give them bioactive properties, including food, health supplements, cosmetics, skincare products, and shampoos, just to name a few (Figure 2). However, to be useful as additives, any impurities (unwanted compounds) in the bioactive extracts should be removed or minimized. Impurities can include other components of the leaves, such as sugars and trace minerals.

- Figure 2 - Many fruits and vegetables, including the parts that are usually discarded, contain bioactive compounds.

- These can be extracted into liquid or powder form with concentrations higher than those found naturally. There are many applications for these natural bioactive extracts, such as in health supplements, cosmetics, and other products.

Making tea from the leaves of plants can be considered a type of extraction. To make tea, hot water is poured over the leaves and left to rest for a few minutes. The hot water separates some compounds from the solid leaves and those extracted compounds are dissolved in the hot water, which is the solvent. One disadvantage of hot water extraction is that heat-sensitive compounds may be broken down by the high temperature of the water. Another disadvantage is that tea contains low concentrations of the extracted compounds, because these compounds are only present in small amounts in the leaves. Techniques such as freeze concentration or evaporation can be used to concentrate solutions. For example, think of frozen orange juice concentrate, in which excess water is removed from the juice and the flavor is concentrated. To obtain large quantities of bioactive compounds, common extraction methods often use toxic chemicals as solvents. These processes may also require high temperatures and long extraction times (usually hours) to improve the extraction yield. The extraction yield tells us the amount of a bioactive compound that is extracted in the solvent, compared to the amount of that same compound present in the leaves. Therefore, the extraction yield is an important measure of how well the extraction worked.

Salting-Out: An Eco-Friendly Method of Extraction

We used a method of extraction called salting-out to extract bioactive compounds from haskap leaves. This process uses food-grade alcohol, water, and salt. Our study confirmed that salting-out is an eco-friendly method of extraction, since we used non-toxic alcohol and salts that are not harmful.

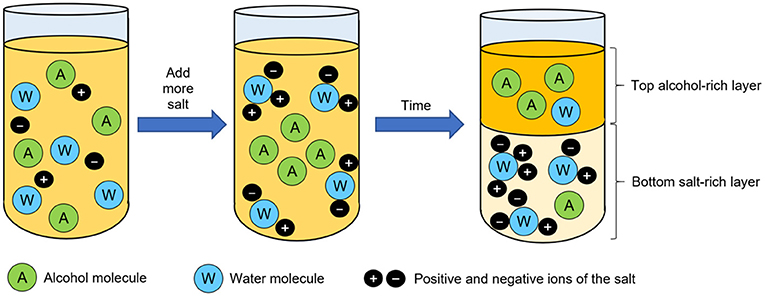

So how does salting-out work? To understand this method, it is first necessary to review some important properties of the alcohol, water, and salt that we use in this process. Let us consider the salt first, and let us use sodium chloride (table salt) as an example. The chemical formula for table salt is NaCl. When it is dissolved in water, this molecule separates into its charged ions: Na+ and Cl-. Water is a polar molecule, meaning that one side of the molecule has a slightly negative charge and the other side has a slightly positive charge. Since opposite charges attract, the Na+ and Cl- ions will both be attracted to the water molecules. What about alcohol? Alcohol is not as polar as water, so in a solution of alcohol, water, and salt, the salt molecules will be more attracted to the water than to the alcohol. As a result, when enough salt is added to a water-and-alcohol solution, the alcohol will be excluded and will separate. We will see two separate layers form: a top, alcohol-rich layer and a bottom salt-rich layer. The alcohol floats on top of the salt solution because it has a lower density (Figure 3).

- Figure 3 - The salting-out process.

- At low salt concentrations (left), the water and alcohol are fully mixed. At higher salt concentrations (middle), the salt ions are strongly attracted to the polar water molecules. Many of the alcohol molecules will then be excluded and form a separate top layer (right). When leaves or other plant parts are added, the bioactive substances will separate into one of the layers based on their polarity and the way they react to the solution.

So, to perform salting-out, haskap leaves are added to a solution of water, alcohol, and salt. The bioactive compounds in the haskap leaves will move into either the top or bottom layer, depending on their polarity and how they respond to the solution. We focused on bioactive compounds called polyphenols, which were extracted into the top layer. So, the top layer formed our haskap leaf extract, made of bioactive polyphenols and the alcohol-rich solvent. The bottom phase, containing most of the impurities, was discarded.

In our study, the salting-out experiments took place at room temperature and the two separate layers were visible after only 5 min, indicating that rapid extraction occurred. We determined the type of salt, the alcohol and salt concentrations, the extraction time, and the amount of leaves needed to achieve the maximum extraction yield [4]. For instance, 10% by weight of the salt sodium phosphate, mixed with 37% ethanol and 53% water, had the highest extraction yield when 0.5% haskap leaves by weight were added for 5 min [4].

The salting-out process has been shown to provide higher extraction yields than other extraction methods [5]. In addition, the salting-out method reduces the number of post-extraction steps that are needed, which is an advantage. For example, when the bioactive compounds are concentrated in the top layer and the impurities remain in the bottom layer, there is no need for a separate purification step, which is often required with other extraction methods. In this way, the salting-out process can save energy, time, and money.

Looking Ahead

Since we used food-grade alcohol and salt in the salting-out process, the haskap leaf extracts obtained from salting-out could be used in foods, health supplements, and other products. For example, as an alternative to plastic packaging, we developed plant-based packaging films that contain haskap leaf extracts [6]. Hopefully these films will be an environmentally friendly way of improving the shelf-life of packaged fruits and vegetables. Our study has shown that haskap leaves can be processed in an eco-friendly way and turned into useful products. So, the next time you pick up a berry, fruit, or vegetable, think about the leaves, stems, peels, rinds, and seeds that are often thrown away. They may contain valuable bioactive compounds that are worth recovering!

Funding

Funding is from the Natural Sciences and Engineering Council of Canada (NSERC) through a Discovery Grant (RGPIN 04397-20).

Glossary

Bioactive Compounds: ↑ Substances that can work within the body to promote good health.

Extraction: ↑ Separation of specific compounds from their source.

Impurities: ↑ Unwanted compounds in the extraction process. Examples include other components of the leaves, such as sugars, fibers, and trace minerals.

Solvent: ↑ A liquid that can dissolve other substances. When salt is dissolved in water, water is the solvent.

Extraction Yield: ↑ The amount of a bioactive compound extracted divided by the total amount originally in the leaves. This number tells us how well the extraction worked.

Salting-out: ↑ Separation of two solutions with different polarities which is caused by high salt concentrations.

Ions: ↑ Electrically charged molecules where positive ions are indicated by a “+” while negative ions are shown with a “–” sign.

Polar: ↑ Polar molecules have uneven negative and positive charge distribution.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Original Source Article

↑Chong, K. Y., Stefanova, R., Zhang, J., and Brooks, M. S. -L. 2020. Aqueous two-phase extraction of bioactive compounds from haskap leaves (Lonicera caerulea): comparison of salt/ethanol and sugar/propanol systems. Sep. Purif. Technol. 252:117399. doi: 10.1016/j.seppur.2020.117399

References

[1] ↑ Oszmiański, J., Wojdyło, A., Gorzelany, J., and Kapusta, I. 2011. Identification and characterization of low molecular weight polyphenols in berry leaf extracts by HPLC-DAD and LC-ESI/MS. J. Agric. Food Chem. 59:12830–5. doi: 10.1021/jf203052j

[2] ↑ Smith, M. A. L., Marley, K. A., Seigler, D., Singletary, K. W., and Meline, B. 2000. Bioactive properties of wild blueberry fruits. J. Food Sci. 65:352–6. doi: 10.1111/j.1365-2621.2000.tb16006.x

[3] ↑ O’Connor, J. 2018. Better than blueberries? Introducing Canada’s new super food — the haskap berry. National Post. Available online at: https://nationalpost.com/news/canada/better-than-blueberries-introducing-canadas-new-super-food-the-haskap-berry

[4] ↑ Chong, K. Y., Stefanova, R., Zhang, J., and Brooks, M. S.-L. 2020. Aqueous two-phase extraction of bioactive compounds from haskap leaves (Lonicera caerulea): comparison of salt/ethanol and sugar/propanol systems. Sep. Purif. Technol. 252:117399. doi: 10.1016/j.seppur.2020.117399

[5] ↑ Sánchez-Rangel, J. C., Jacobo-Velázquez, D. A., Cisneros-Zevallos, L., and Benavides, J. 2016. Primary recovery of bioactive compounds from stressed carrot tissue using aqueous two-phase systems strategies. J. Chem. Technol. Biotechnol. 91:144–54. doi: 10.1002/jctb.4553

[6] ↑ Chong, K. Y., Yuryev, Y., Jain, A., Mason, B., and Brooks, M. S.-L. (2021). Development of pea protein films with haskap (Lonicera caerulea) leaf extracts from aqueous two-phase systems. Food Bioprocess Technol. 14:1733–50. doi: 10.1007/s11947-021-02671-6